It's worth observing that to be able to make pellets, you'll need specialized equipment. Even though it might be easy to develop a homemade pellet mill, I've not seen a trusted productive one out of action yet. If actually you realize of one, you can leave a comment having a link to it. Nevertheless, you will find two primary needs, the raw material, and also the equipment to create the pellets.

Raw Material

You may make wood or biomass pellets from a variety of materials. Both softwood and hardwood are generally used and convey excellent results. What's interesting though is the fact that you can also make biomass pellets from a multitude of materials. A few of the possible elements are - switch grass, grain, corn cobs, corn stalks, paper, saw dust, distiller grain, and many more. You will find many potential materials you can use with higher results. The most popular guideline is when you are able to reduce how big your selected biomass into granular form, you may make pellets from this.

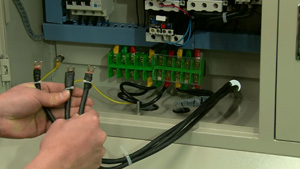

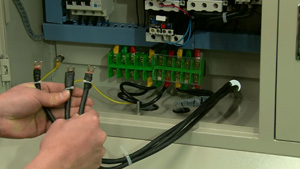

How to Adjust Moisture Conten and Instal Circuit

The Equipment

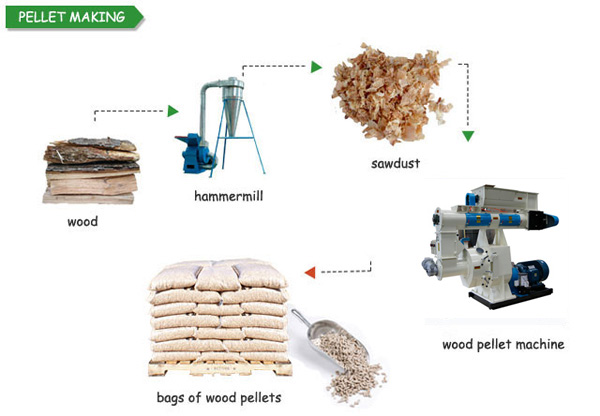

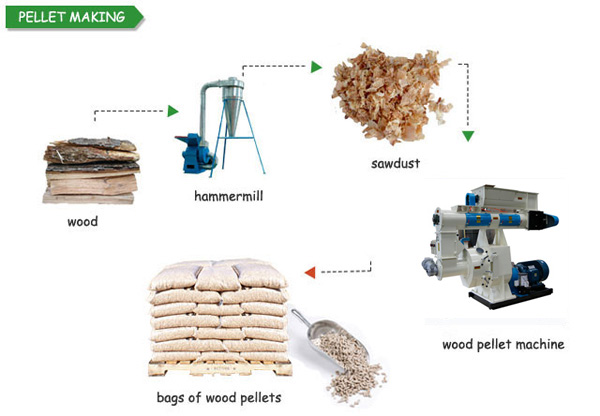

You will find several items which are used available wood pellet manufacturing process. These may include hammer mills, dryers, pellet machines, coolers, bagging machine, and central heating boilers to title a couple of from the major ones. Observe that to a massive commercial manufacturing pellet line. If you are making pellets on the more compact use at home scale, You can manage without many of these. Typically, homemade wood or biomass pellets come in a small-scale pellet mill. For the way large how big the raw material is, you may even want to use a little hammer mill. The aim would be to result in the contaminants more compact than 1/4". In case your raw material is more compact than 1/4" to start with, when utilizing saw dust for example, you will not require a hammer mill.

Different Pellet Machines:

The Procedure

As the saying goes, the demon is incorporated in the particulars. Based on what your raw materials are switch grass versus saw dust for example, the "recipe" can change. We'll use dried wood because the raw material for that example that follows.

First, when the raw material is bigger than 1/4", it's divided within the hammer mill to some more compact particle size. Next, the raw fiber is either put in the pelletizer or heated with steam, pressure, a mix of both. This will cause the naturally sourced lignin to plasticize and contain the pellet together after it goes through the pelletizer and cools lower.

Wood Pellets Production Procedure

Make Wood Pellets

Lignin is really a natural substance that's present in wood and functions like glue. In case your raw material is not wood and does not have lignin, another binding agent will have to be put into contain the pellets together. This binder will rely on what particular raw stock you use. A few of the generally used binders are vegetable oil, clay, starch, oil, or wax to title a couple of.

Within the pelletizer, the raw material is routed via a die and paint rollers. The paint rollers pressure the fabric via a die that provides the pellets their characteristic tubular shape. After they exit the pelletizer, they're then permitted to awesome lower. This will cause the pellets to harden, and enables these to retain their shape.

Finally, the pellets should be permitted to dry up. A moisture content of from 5% - 15% ought to be sufficient. The precise percentage will rely on the raw material that you are using to create your pellets.

Français

Français Русский

Русский Español

Español