| |

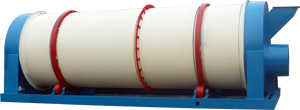

Rotary drum dryer is also famous as rotary kiln, which is mainly applied to cut down or minimize the moisture content of agro-forestry wastes like sawdust for further pelletizing process. The rotary drum dryer consists of a large rotating cylindrical tube. The rotary drum dryer is a special design to dry the wood materials together with other biomass material powders up to 40% moisture content to 15%, which is needed to make pellets. A complete drying system consists of two main parts: furnace which is providing heat source for drying raw material; dryer which is rotoried and dried the materials to 15% moisture content by the hot air from the furnace.

Different Layers of Rotary Drum Dryers:

Technical Parameters:

|

Model |

Diameter(mm) |

Length(m) |

Power(kw) |

Speed rotation(r/min) |

|

HZG6 |

600 |

4,5,6,7,8 |

3-5.5 |

3-20 adjustment |

|

HZG8 |

800 |

4,6,7,8,9,10 |

5.5-7.5 |

3-20 adjustment |

|

HZG10 |

1000 |

6,7,8,9,10,11,12 |

5.5-7.5 |

3-20 adjustment |

|

HZG12 |

1200 |

6,8,10,12,14,16 |

7.5-11 |

3-20 adjustment |

|

HZG15 |

1500 |

8,10,12,14,16,18 |

11-15 |

3-20 adjustment |

|

HZG18 |

1800 |

8,10,12,14,16,18,20 |

15-18.5 |

3-20 adjustment |

|

HZG22 |

2200 |

10,12,14,16,18,20,22,25 |

18.5-22 |

3-20 adjustment |

|

HZG24 |

2400 |

12,14,16,18,20,22,25 |

22-30 |

3-20 adjustment |

What kinds of raw materials need to be dried by rotary drum dryer?

Usually, the rotary drum dryer process the raw materials including agro-forestry wastes, sawdust, animal wastes and animal feeds in pellet mill plant or feed pellet production line.

Our dryer features single and multi-layers technology that moves materials through the drum in an air stream made by the dryer induced-draft fan. The multiple layers are mechanically interlocked to rotate at the same speed. As the drum rotates, the material is repeatedly showed into the dryer hot gas.

|

| |

|

|

| |

|

| |

|

| |

| |

Mobile Pellet Plant

|

|

| |

200-300KGS Per Hour

Less labor intensive, automatic process, cooled pellets pack quickly

|

|

|

|

| |

|

|

| |

|

| |

|

| |

|

|

Français

Français Русский

Русский Español

Español